High-Volume Precision Machining

At Attex, we offer specialized high-precision machining solutions for serial production, ensuring dimensional accuracy, repeatability, and reliable delivery times.

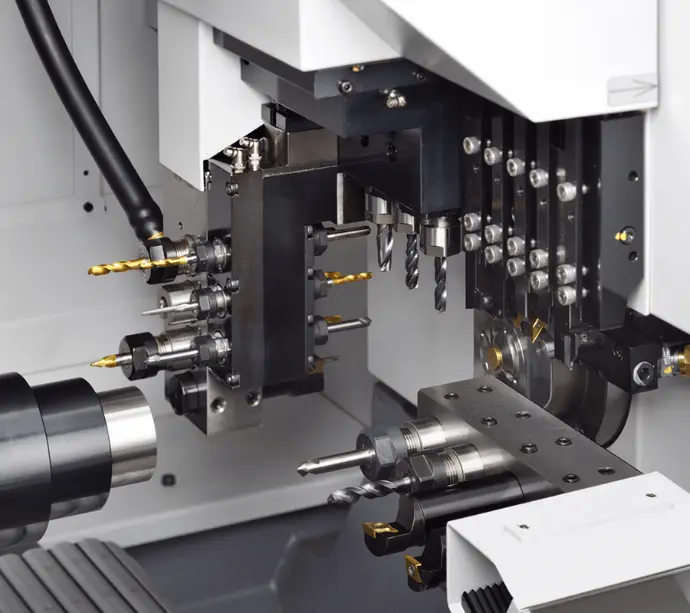

We have state-of-the-art CNC machinery, high-performance cutting tools, and a strict quality control system that guarantees tight tolerances and flawless finishes — even in large-scale projects.

Our expertise covers a wide range of materials — from steels and aluminums to engineering plastics — and we adapt to each client’s needs, optimizing processes to achieve competitive costs without compromising quality.

Whether for automotive, aerospace, medical, or industrial components, we operate with a focus on efficiency, consistency, and reliability, supported by a highly skilled technical team. Preguntar a ChatGPT

Advantages of Our Service:

- Continuous and stable large-batch production.

- Strict compliance with technical specifications.

- Dimensional inspection using precision measuring equipment.

- Reduced downtime and optimized costs.

We take precision to the next level in every part we deliver.

Process Features

Swiss-type CNC turning is a specialized machining process designed to produce high-precision parts, particularly for small diameters and complex geometries.

-

Automatic Material Feeding

- The process begins with material bars continuously loaded through an automatic bar feeder. Preguntar a ChatGPT

- This enables uninterrupted production and maximizes efficiency by reducing downtime and manual handling.

-

Guided Clamping and Cutting

- Unlike conventional lathes, the Swiss-type lathe holds the bar very close to the cutting tool using a guide bushing, minimizing vibrations and ensuring tolerances of up to ±0.002 mm.

- Operations such as external turning, milling, grooving, drilling, and threading are performed in a single setup.

-

Simultaneous Multi-Axis Operations

- The multi-axis design and use of live tooling allow operations on both the front and back of the part simultaneously, reducing cycle time and improving repeatability.

-

Integrated Quality Control

- During production, in-process measurements are performed using probes and digital comparators to ensure each part meets specifications. Preguntar a ChatGPT

- The first parts of each batch are inspected using high-precision metrology instruments such as micrometers, profile projectors, or CMMs (coordinate measuring machines).

- A statistical process control (SPC) system is implemented to detect deviations before they impact production.

-

Material Handling and Preservation

- Bars and finished parts are handled using padded trays and containers to prevent surface damage.

- High-quality lubrication and cooling are used to extend tool life and maintain dimensional stability.

- Finished parts are cleaned and, when necessary, special coatings or packaging are applied to protect them during transportation.

This system combines Swiss precision technology, automation, and rigorous quality control, making it ideal for sectors such as medical, aerospace, automotive, and electronics, where accuracy and reliability are essential.